iFilt® Diamond Filter

Advanced Cross-Flow Filtration

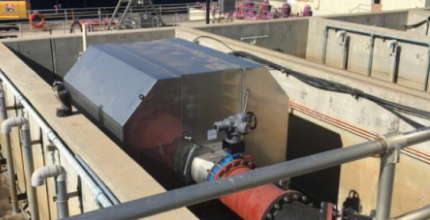

The iFILT® Diamond Filter is an advanced filtration system designed specifically for wastewater treatment following the secondary clarifier. Utilizing state-of-the-art fluid mechanical tools and computational fluid dynamics (CFD), it achieves exceptional energy efficiency and effective removal of floating substances within a compact footprint. The cross-flow filtration principle underpins its outstanding hydraulic performance, while its construction from high-quality stainless steel ensures durability and low maintenance. The iFILT® Diamond Filter simplifies installation, requiring only connections to supply and discharge pipework and electrical supply, making it a practical and efficient solution for modern wastewater treatment plants.

The Invent iFILT® Diamond Filter is an innovative filtration system designed to achieve high throughput and superior separation results. By combining cross-flow filtration with a unique diamond-shaped filter construction, it ensures minimal pressure loss and efficient filtration. The continuous rotation of the filter enhances tangential-dynamic filtration, reducing the frequency of backwash cycles and thereby decreasing energy consumption. The design also features a fluid-mechanically optimized distributor that eliminates leakage and filtrate contamination, ensuring reliable and clean filtration performance.

Wastewater enters the filter via a fluid-mechanically optimized distributor connected directly to the rotor center. This eliminates the need for an expensively sealed rotary union, preventing leakage and filtrate contamination.

The wastewater flows through the diamond-shaped filter wheels from the inside towards the outside. The continuous rotation of the wheel initiates tangential-dynamic filtration, ensuring high throughput and sharp cut-off of particles.

As solids accumulate on the filter material, the hydraulic resistance increases, causing a gradual rise in the water level within the filter.

When the water level reaches a predetermined point, a backwash cycle is triggered.

Spray nozzles wash the filter from the outside, removing retained solids. The filter continues to rotate during backwashing, flushing the solids into an internal collector flume.

The collected solids are drained off separately from the filtrate and can be reintroduced to the wastewater treatment plant’s influent.

The backwash water pump uses filtrate, eliminating the need for an external water supply and reducing energy consumption.

Developed with state-of-the-art fluid mechanical tools and computational fluid dynamics (CFD) for optimal performance.

Energy-efficient operation and low maintenance requirements lead to significant cost savings over time.

High-quality stainless-steel construction ensures long-term reliability and resistance to corrosion.

Optimized for space efficiency, making it suitable for facilities with limited space.

Dispenses with complex sealed rotary feedthroughs in the inlet area, simplifying maintenance requirements.

Designed to be particularly energy-efficient, reducing operational costs.

Easy installation and integration into existing systems provide flexibility for various wastewater treatment applications.

Continuous rotation and optimized filtration ensure consistent performance and reliable effluent quality.