Ultra-Scraper® Sludge Collector

Reciprocating Linear Sludge Scraper

The MRI Ultra-Scraper Sludge Collector offers a robust, efficient, and reliable solution for sludge removal in water treatment plants. Its advanced operating principle, combined with key features such as heavy-duty components, reciprocating linear blades, factory pre-assembled transport racks, and a signature control system, ensures thorough sludge removal, simplified maintenance, and enhanced overall performance.

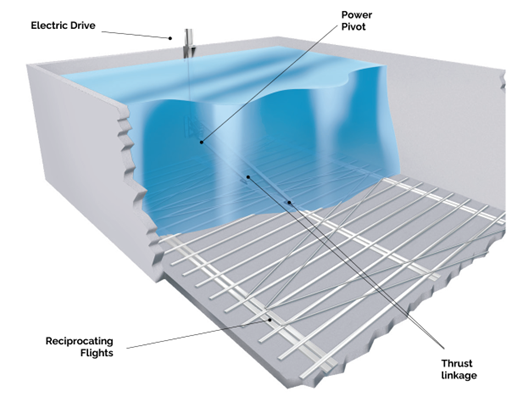

MRI’s Ultra-Scraper is an advanced sludge collection system designed for high efficiency and reliability in wastewater treatment. The Ultra-Scraper features double-acting, reciprocating linear blades that significantly enhance sludge removal efficiency, making it twice as effective as conventional scrapers.

For a detailed understanding, refer to the image under the “Principle of Operations.”

As water enters the sedimentation basin, suspended solids begin to settle to the bottom due to gravity. The Ultra-Scraper is positioned to effectively collect these settled solids.

The core feature of the Ultra-Scraper is its double-acting, reciprocating linear blades. These blades move back and forth in a linear motion, scraping the settled sludge off the basin floor and collecting it efficiently. This design doubles the performance compared to conventional scrapers by ensuring that all settled solids are collected, even those that are typically left behind.

Two transport racks with scraper blades are assembled without field welding, enhancing structural integrity and ease of maintenance. These racks guide the movement of the scraper blades and ensure that the collected sludge is directed towards the discharge point.

The scraper blades are powered by a reliable drive unit, which can be either hydraulic or electric. This drive unit provides the necessary force for the blades to move through the settled sludge and collect it efficiently.

A cross collector is integrated into the system to optimize sludge removal. As the scraper blades collect sludge, it is transported to the cross collector, which then channels it to a designated discharge point. This ensures that sludge is removed from the basin in a controlled and consistent manner.

MRI’s signature control system allows for precise control and easy adaptability of the scraping process. Operators can adjust the settings to match specific operational needs, ensuring that the scraper operates at optimal efficiency under varying conditions.

Built with high-quality, durable materials to withstand the demanding conditions of water treatment plants.

The backward and forward action of the scraper blades significantly enhances the removal of solids.

Pre-assembled components reduce on-site assembly time and eliminate the need for field welding.

Ensures even and efficient removal of sludge across the entire basin.

Designed and manufactured in-house to meet specific project requirements, offering easy integration with existing systems.

The Ultra-Scraper operates at a much higher velocity than traditional chain and flight systems, enabling efficient removal of thick, heavy sludge.

Minimal moving parts and robust construction reduce maintenance needs and ensure easy access for any required servicing.